Clean Energy Research Platform

About the Platform

The Clean Energy Research Platform at KAUST develops scalable, high-impact technologies that support Saudi Arabia’s energy transition and circular carbon economy goals. Focused on applied research and commercialization, the Platform targets critical challenges in decarbonization, sustainable fuels, and industrial emissions.

With more than 40 global partnerships and over $50 million in external funding, the Clean Energy Research Platform is advancing KAUST technologies to pilot and demonstration stages. These efforts align with Saudi Vision 2030 and the RDIA agenda, delivering innovations with clear commercial pathways. Our core technologies focus on emission-sensing technologies, fuels and chemical characterizations, combustion technology and diagnostics, and photocatalysis and photoelectrocatalysis for application to the circular carbon economy, the waste-to-value chain, fuel synthesis, carbon-free fuel synthesis, fuel cells and electrolyzer systems, and mineral processing.

Platform Infrastructure

The Clean Energy Research Platform operates more than 3,100 square meters of indoor lab space, along with additional outdoor scale-up facilities, to advance energy research — from fundamental studies to applied, industrial-scale solutions. Core facilities include:

-

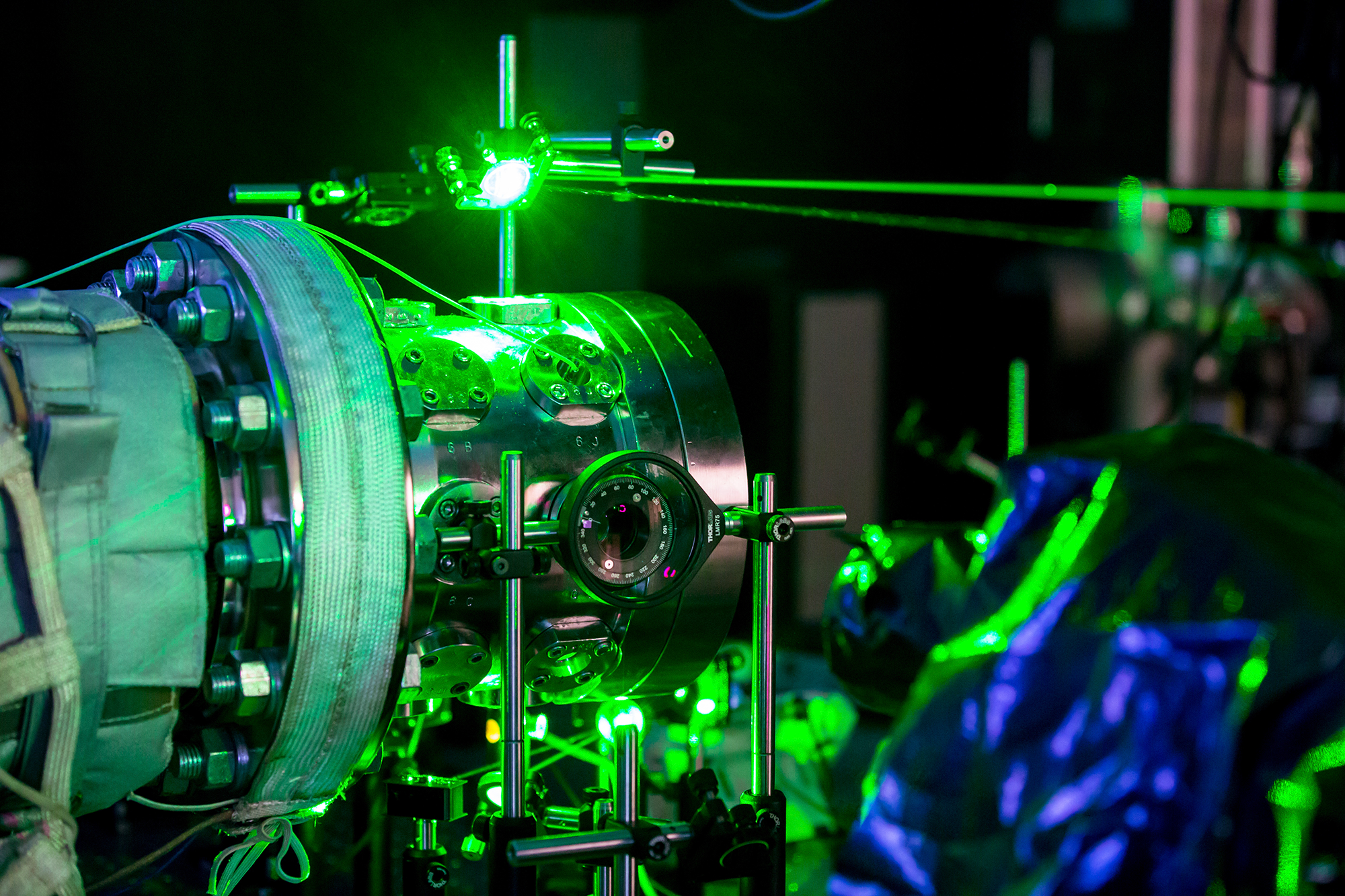

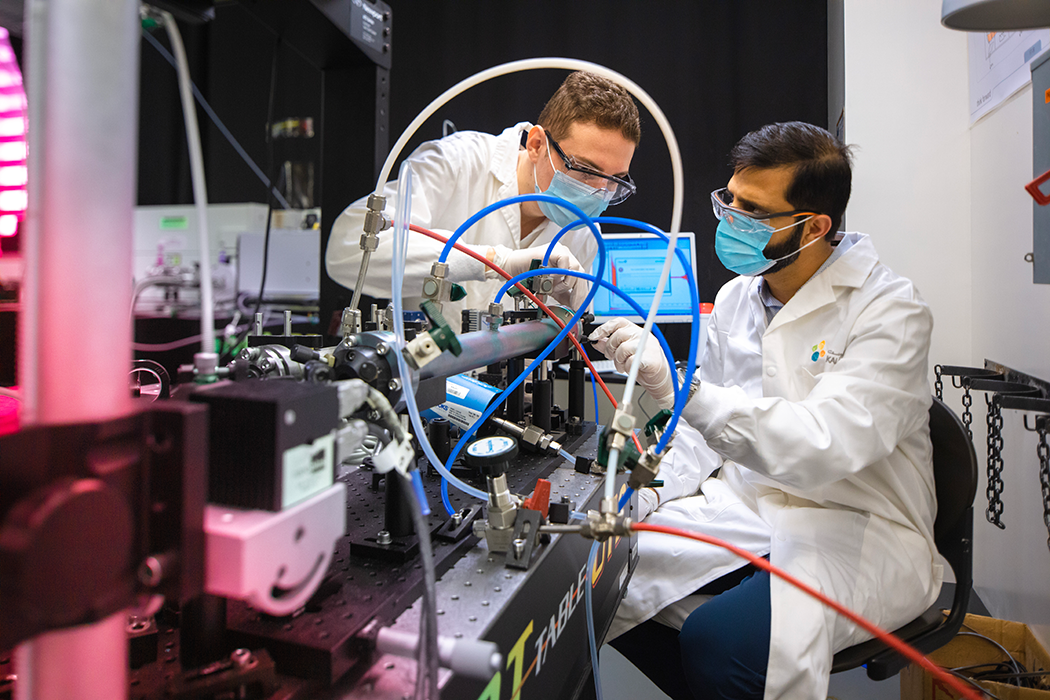

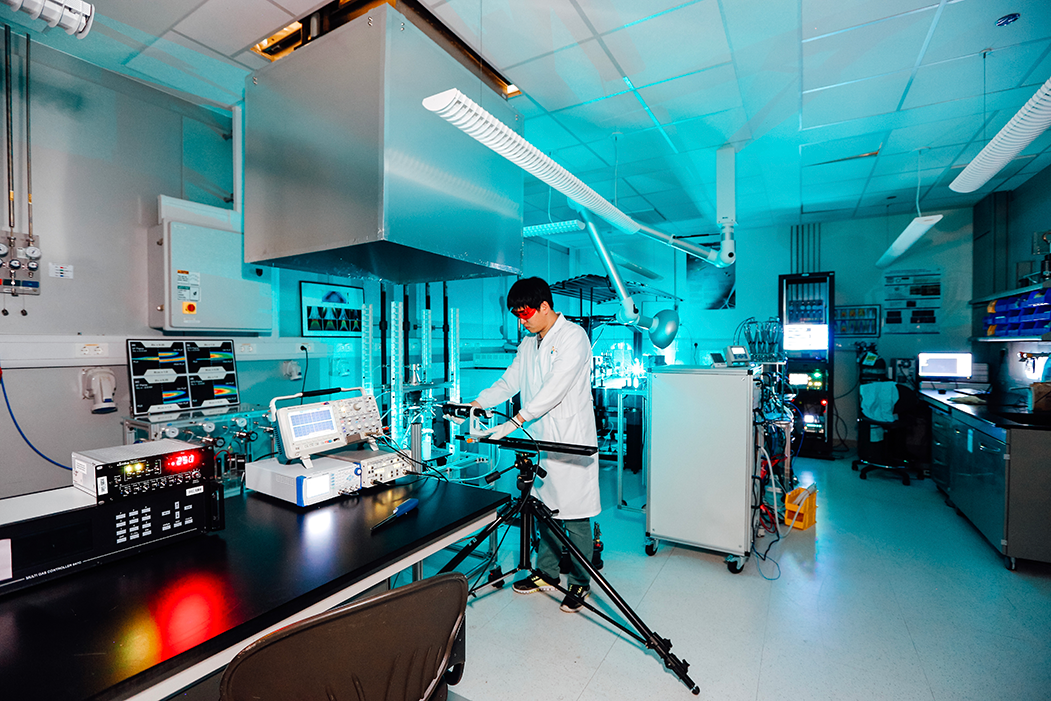

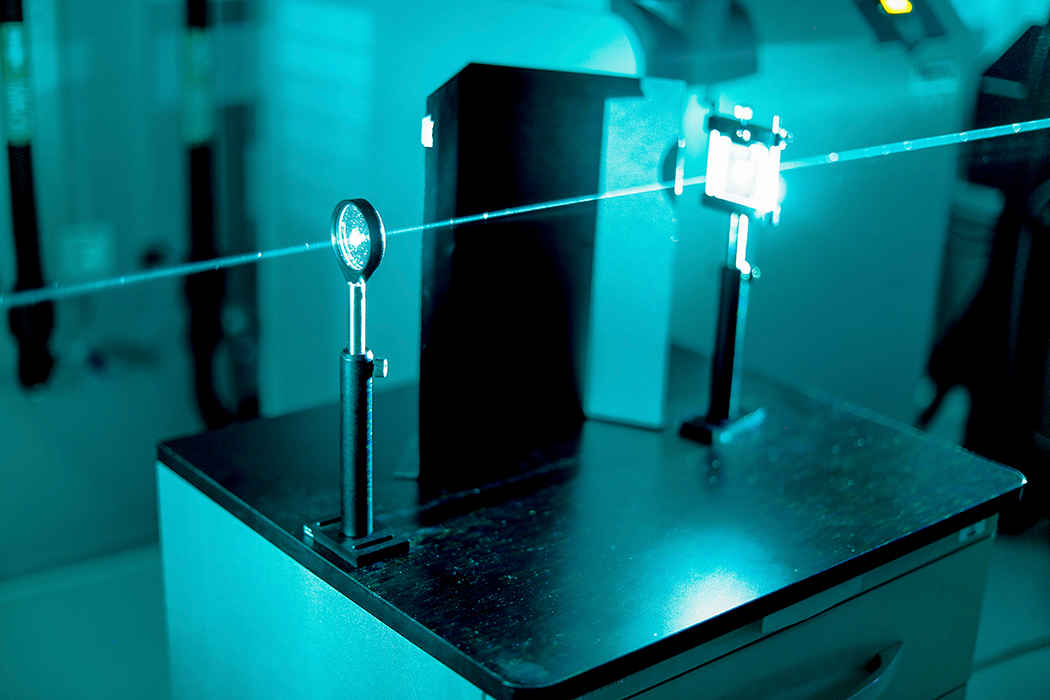

Combustion and In-situ Laser Diagnostics Laboratory: Equipped with advanced laser and imaging systems to study flame dynamics, fuel-air mixing, and pollutant formation using techniques such as particle image velocimetry, planar laser-induced fluorescence, laser-induced incandescence, and Raman spectroscopy.

- Chemical Kinetics and Advanced Sensing Laboratory: Measures ignition delay times and rate constants for alternative fuels using shock tubes, a rapid compression machine, and the Advanced Fuel Ignition Delay Analyzer, with laser-based diagnostics for sensor development.

- Combustion Chemistry and Plasma Laboratory: Focuses on pyrolysis of conventional and alternative fuels, combustion chemistry modeling, plasma-assisted combustion, and heavy fuel oil studies. The lab is equipped with microwave reactors, gas chromatography, and Fourier-transform infrared spectroscopy.

- High-Pressure Combustion Laboratory: Simulates industrial conditions up to 50 bar for studying autoignition, flame stability, and pollutant formation with optical diagnostics.

- Engine and Fuels Laboratory: Houses six engine test platforms with optical access, emission analyzers, and laser diagnostics to evaluate advanced fuels, lubricants, and combustion strategies.

- Low-Carbon Energy Conversion and Storage Laboratory: Focuses on solar-to-hydrogen systems, seawater electrolysis, and carbon dioxide conversion using nanomaterials and in-situ flow characterization.

Clean Energy Research Platform

Clean Energy Research Platform

Clean Energy Research Platform

Clean Energy Research Platform

Clean Energy Research Platform

Clean Energy Research Platform

Equipment

High-impact instruments supporting research

1. Proton Exchange Membrane Fuel Cell Plant

Manufacturer: Toyota

65kWe Toyota Mirai’s type 2 full balance of plant, equipped with peripheral systems to allow to test drive cycles, climate conditions and impact of pollutants.

2. G100 Proton Exchange Membrane Fuel Cell Testbed

Manufacturer: AVL/Green light innovation

G100 series, up to 120 oC operation, equipped with multiple gas detections and automatic humidifier, capable to handle single and stacks up to 2kW fuel cells of cross-sectional area of 12 to 25 cm2

3. E60 Proton Exchange Membrane Electrolyser Testbed

Manufacturer: AVL/Green light innovation

E60 series, up to 2 kW, 12 to 25 cm2 cross-section cells and short stacks can be tested. Testbed coupled with multiple gas detection systems allow safe operation. Diagnostics systems such as Cell Voltage Monitor, Impedance analyzer, Cyclic & Linear Voltammetry are integrated with Emerald software for automatic diagnostics.

4. 855-SOFC (Solid Oxide Fuel Cell) Test System

Manufacturer: Scribner

Suitable to test button cells and planar cells with a multi range electronic load of 5/25/50 A, 100 W, 20 V. The system is programmable with power supply for SOEC (Solid Oxide Electrolyser) mode operation – 100 A / 5 V. Power supply mode includes voltage & current control with constant, scanning & step-stair experiments. Includes Furnace Control hardware with redundant over-temperature protection.

The system is capable of handling constant or stoichiometric-controlled reactant flow rate and zero-volt capability.

5. High Pressure Combustion Duct

Manufacturer: Custom made

Duct can house burners working on gaseous fuels up to 100 kWth, with a flexibility to synthesize a variety of fuels, including hydrocarbons, H2, NH3. Designed up to 40 bars and tested up to 25 bar.

6. Carbon Capture and Sulfur Co-capture

Manufacturer: Custom built

The Cryogenic Carbon and Sulfur Co-capture (CCSC) trailer rig from KAUST is an innovative, mobile system designed to capture multiple pollutants—including high-purity CO₂ (99.9%), SO₂, NO₂, and particulate matter (PM)—using a single cryogenic technology. Developed for flexible deployment at Kingdom point source locations, the CCSC rig demonstrated its capabilities at the Heavy Fuel Oil (HFO)-fired Power Plant of our key stakeholder, with minimal impact on existing infrastructure and operations.

0.25 tons per day operatable unit, can handle a variety of exhaust gas flumes ranging from low to high CO2 streams. Capturs 98% of CO2 emissions from flue gases with a capture efficiency of 99%, can be used in food processing applications. The unit is built on wheels to demonstrate the concept across the Saudi Arabia

7. Oxidative Desulpherization Unit

Manufacturer: Custom built

10 tons per day demonstratable unit that can reduce Sulphur from base oils using a innovative cavitation technique. Tested at pre-pilot scale at industrial sites and ready to be deployed for commercial operation.

8. Entrained Flow Gasifier

Manufacturer: Custom made

Unit capable of operating at 0.25 tons per day, designed for vacuum residue, operable at high pressures to test real life scenarios.

9. Shock Tubes

Manufacturer: Custom made

Low Pressure Shock Tube

•18 m long, ø 14.2 cm SS tube

•Withstands 1 - 20 bar & 500 - 4000 K

•Pre-heat capability up to 200 0C

High Pressure Shock Tube

•14 m long, ø10 cm SS tube

•Withstands 1 - 200 bar & 600 - 3000 K

•Pre-heat capability up to 200 0C

Applications:

•Ignition delays time measurements

•Speciation with laser diagnostics

•Elementary reactions rate measurements

•Electron density measurements

•High-speed imaging

•Chemical Kinetics mechanism validation

10. Solar Simulator

Manufacturer: Custom made

Nominal capacity of 42 kWe with flexible power operation and a focal point at 60-80 mm diameter. Designed to study the impact of renewable energy on industrial processes

Team Expertise

- Affiliated Faculty

- Platform Staff

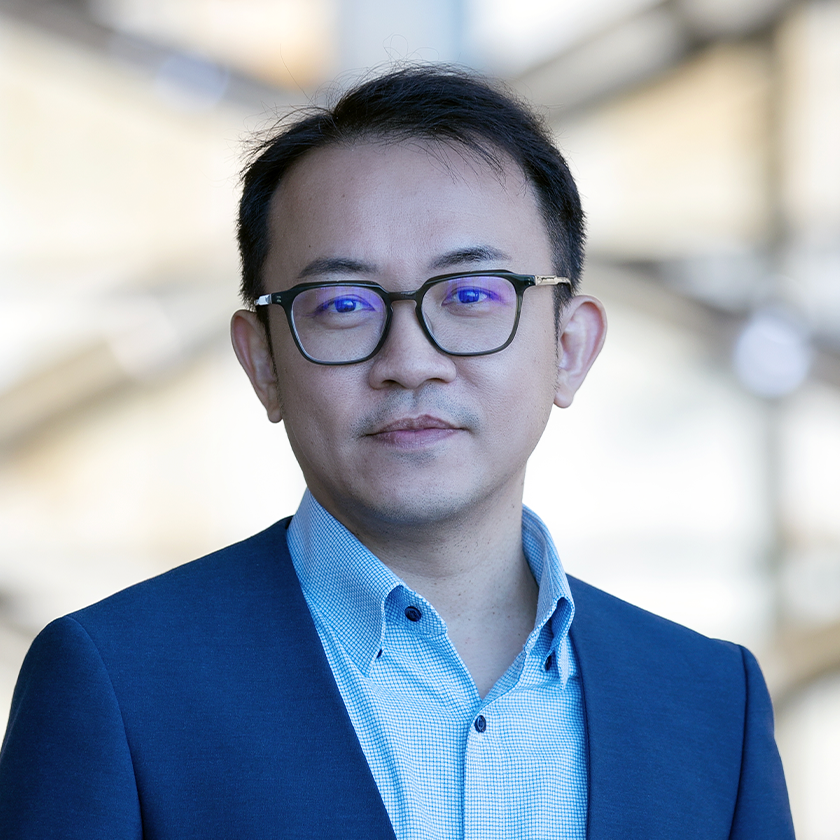

Hong G. Im, Ph.D.

Deputy Chair of Clean Energy Research Platform, Professor of Mechanical Engineering

Hong G. Im, Ph.D.

Deputy Chair of Clean Energy Research Platform, Professor of Mechanical Engineering

Research Expertise

The Clean Energy Research Platform brings together multidisciplinary expertise to support national priorities in sustainability, decarbonization, and industrial innovation. Innovations and collectives include the following: