Supercomputing and 3D printing capture the aerodynamics of F1 cars

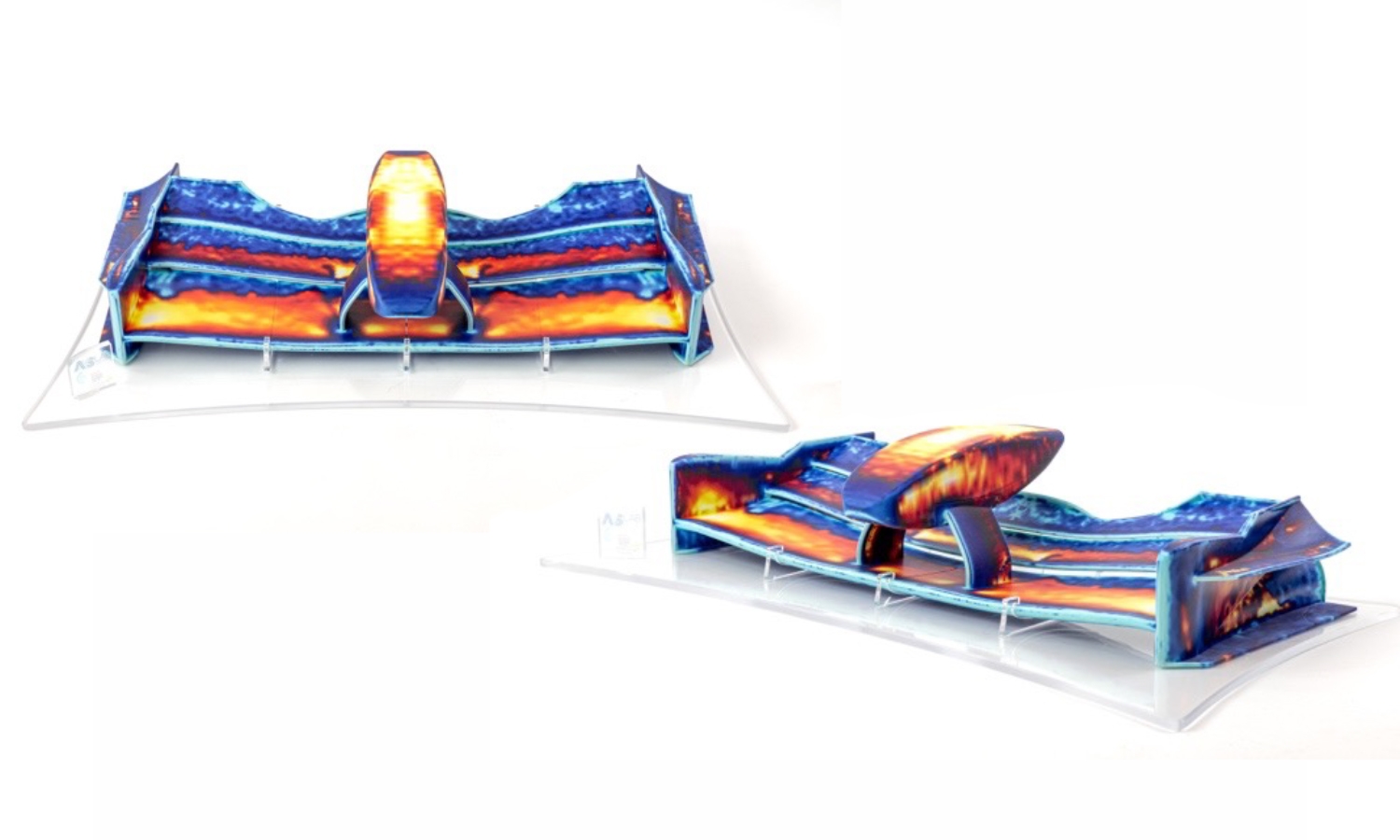

A photo of the 3D color printed McLaren 17D Formula One front wing endplate. The colors visualize the complex flow a fraction of a millimeter away from the wing's surface. Photo: KAUST

In Formula One race car design, the manipulation of airflow around the car is the most important factor in performance. A 1% gain in aerodynamics performance can mean the difference between first place and a forgotten finish, which is why teams employ hundreds of people and spend millions of dollars perfecting this manipulation.

Of special interest is the design of the front wing endplate, which is critical for the drag and lift of the car. Dr. Matteo Parsani, associate professor of applied mathematics and computational science at King Abdullah University of Science and Technology (KAUST), has led a multidisciplinary team of scientists and engineers to simulate and 3D color print the solution of the McLaren 17D Formula One front wing endplate. The work is the result of a massively high-performance computing simulation, with contributing expertise by research scientist Dr. Lisandro Dalcin of the KAUST Extreme Computing Research Center (ECRC), directed by Dr. David Keyes, and also the Advanced Algorithm and Numerical Simulations Lab (AANSLab), and Prototyping and Product Development Core Lab (PCL).

The primary goal of the front wing is to generate a downforce, which forces the wheels deeper into the road and increases tire grip. More grip translates into faster cornering speeds, harder acceleration and braking, and faster lap times. However, the aerodynamics of a Formula One car are extremely complex because of challenges in measuring turbulence, separated flow and ground effects.

Parsani, an expert in high-performance computing for aerodynamics simulations, and the scientists in ECRC used KAUST’s supercomputer, Shaheen XC40, to gain details about airflow around the front wing endplate. Parsani sought cooperation with the PCL to understand and visualize the output of the simulations.

“The data is very large and complex, and I wanted to see what’s happening on the wing. By coloring the flow patterns on the wing, we could clearly visualize some of the key flow features. It is a very elegant modern analogy of Schlieren photography,” said Parsani. “This is an excellent example of the capabilities we can achieve by combining extreme computing and 3D printing at KAUST.”

The KAUST PCL is equipped with a Stratasys 750, one of the very few 3D printers in the world with the color capability needed for the project. Visualizing the massive data set generated by the supercomputer simulations can help engineers to identify additional areas of optimization.

This was no trivial task. The PCL staff engineered and 3D printed the wing with the flow field acquired from the simulations with high fidelity. The ability to compute and visualize in the 3D flow field will have a profound effect on not only race car engineering, but also any industry that demands optimization of these effects in its manufacturing.