MOFs for clean energy

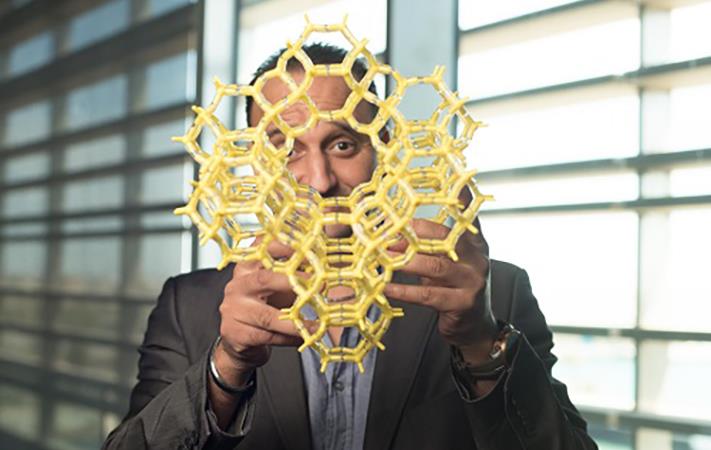

KAUST Professor Mohamed Eddaoudi shows off a model MOF at the University.

Materials developed by researchers at KAUST have the potential to improve the quest for green energy, including the search for cleaner fuels and the means to store various gases.

In recent years, there has been a surge of interest in a group of fabricated materials known as metal-organic frameworks (MOFs). Their flexible structures can be manipulated for a multitude of highly specific applications.

Professor Mohamed Eddaoudi from the University's Physical Science and Engineering Division has devoted his career to designing and building MOFs. The University's Advanced Membranes and Porous Materials Center, where he conducts his research, was purpose-built to support the KAUST ambition of the University becoming a world-class center for research into sustainable clean energy and power.

"The energy costs associated with the separation and purification of industrial commodities such as gases, fine chemicals and fresh water currently represent around 15 percent of global energy production, and the demand for such commodities is projected to triple by 2050," Eddaoudi said. "The ongoing challenge is to develop effective separation and purification technologies that have much smaller energy footprints."

There is also a pressing need to find ways of storing gases—either to remove CO2 from the atmosphere or to enable the storage of cleaner fuels such as hydrogen and methane (CH4) for power. Functional solid-state materials like MOFs could fill this gap in technology.

MOFs are designed from the molecular level up, rather like custom-building with nanoscale Lego bricks. Eddaoudi has developed various design strategies based on the molecular building block approach for the construction of MOFs.

He hopes that improving the processes used to create MOFs will lead to materials being scaled up for use on an industrial scale.

Materials developed by researchers at KAUST have the potential to improve the quest for green energy, including the search for cleaner fuels and the means to store various gases.

In recent years, there has been a surge of interest in a group of fabricated materials known as metal-organic frameworks (MOFs). Their flexible structures can be manipulated for a multitude of highly specific applications.

Professor Mohamed Eddaoudi from the University's Physical Science and Engineering Division has devoted his career to designing and building MOFs. The University's Advanced Membranes and Porous Materials Center, where he conducts his research, was purpose-built to support the KAUST ambition of the University becoming a world-class center for research into sustainable clean energy and power.

"The energy costs associated with the separation and purification of industrial commodities such as gases, fine chemicals and fresh water currently represent around 15 percent of global energy production, and the demand for such commodities is projected to triple by 2050," Eddaoudi said. "The ongoing challenge is to develop effective separation and purification technologies that have much smaller energy footprints."

There is also a pressing need to find ways of storing gases—either to remove CO2 from the atmosphere or to enable the storage of cleaner fuels such as hydrogen and methane (CH4) for power. Functional solid-state materials like MOFs could fill this gap in technology.

MOFs are designed from the molecular level up, rather like custom-building with nanoscale Lego bricks. Eddaoudi has developed various design strategies based on the molecular building block approach for the construction of MOFs.

He hopes that improving the processes used to create MOFs will lead to materials being scaled up for use on an industrial scale.