KAUST Catalysis Platform

About the Platform

The KAUST Catalysis Platform harnesses state-of-the-art catalyst design through an integrated approach combining high-throughput (HTP) screening and artificial intelligence (AI). This powerful synergy enables rapid identification and optimization of catalyst formulations, efficiently narrowing vast candidate libraries into precise, high-performance recipes ready for scale-up.

Lab-scale evaluation employs a diverse suite of reactors, including batch, flow, and fluidized bed systems, paired with comprehensive ex-situ characterization tools, such as nuclear magnetic resonance (NMR), X-ray photoelectron spectroscopy (XPS), and electron microscopy. These capabilities provide detailed insights into catalyst structure, activity, and stability under controlled conditions.

Operando spectroscopic techniques, including infrared (IR), Raman, and X-ray absorption spectroscopy (EXAFS), offer real-time monitoring of catalytic processes, revealing dynamic surface phenomena and mechanistic pathways during operation. This deep understanding drives iterative catalyst refinement and performance enhancement.

By seamlessly integrating AI-driven design, rapid screening, versatile reaction testing, and advanced operando characterization, the Platform delivers innovative, scalable catalytic solutions that meet the evolving demands of energy, environmental, and industrial sectors and exemplifies KAUST’s strategic vision and commitment to fostering impactful industry partnerships aligned with Saudi Arabia’s Vision 2030.

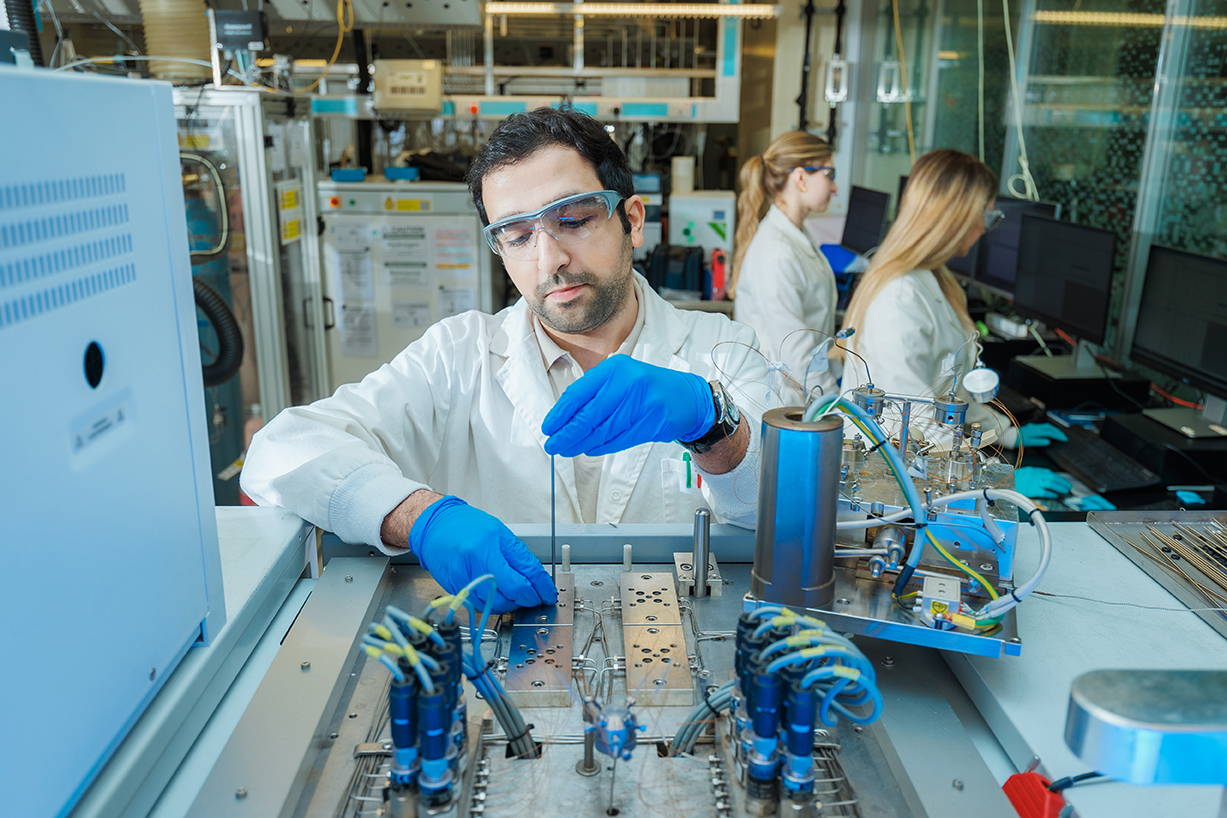

Platform Infrastructure

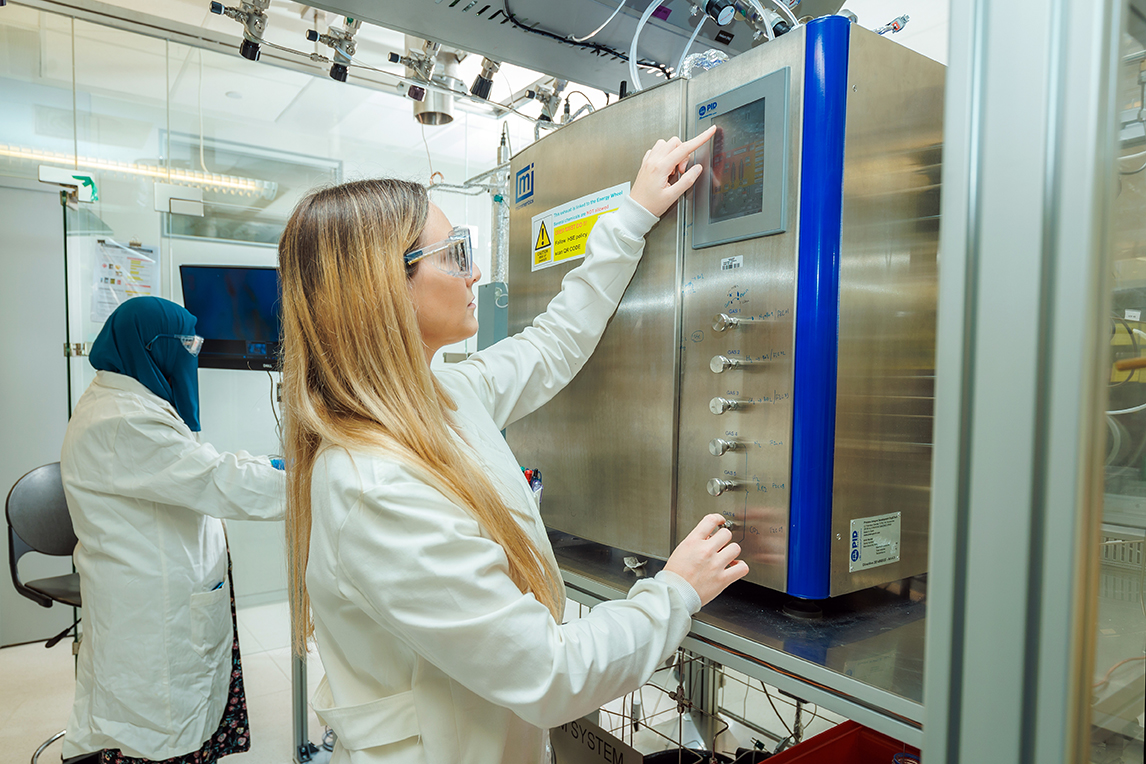

The Platform spans 4,000 m² and serves as a shared research facility supporting 205 users from 8 primary and 5 secondary faculties. The space is organized into four main areas and includes over 100 fume hoods, 300 ventilated enclosures and cabinets, and 75 fridges and freezers to ensure safe handling and storage of materials. The facility manages approximately 27,000 registered chemicals and 270 special gases, including toxic and flammable types, under strict safety protocols. It houses over 200 high-value assets, which are shared based on availability and research needs, enabling efficient use of advanced equipment across disciplines.

KAUST Catalysis Platform

KAUST Catalysis Platform

KAUST Catalysis Platform

KAUST Catalysis Platform

KAUST Catalysis Platform

KAUST Catalysis Platform

Equipment

High-impact instruments supporting research

1. High Throughput flow reactor

Manufacturer: Avantium

The facility is equipped with 4 and 16 reactor units. They provide small-scale fixed-bed reactors to perform simultaneous testing of 4/16 catalytic material samples in a broad range of applications that operate in gas, vapor and trickle phases. The units can handle gases hydrogen, nitrogen, argon, oxygen, carbon monoxide, carbon dioxide ammonia, hydrogen sulfide also alcohols and organic acids. Reaction temperatures can go up to 900°C. On-line GC analysis is installed for fast data retrieval, like conversion, yield and selectivity of the reaction.

2. Synthesis and batch reaction Automatic Platform

Manufacturer: ChemSpeed

The fully automated platform enables precise dispensing of solids and liquids, mixing, heating, and conducting batch reactions up to 300°C and 80 bar, and is also designed for photocatalysis screening under controlled light exposure

3. XPS

Manufacturer: SPECS

Electron Spectroscopy for Chemical Analysis under Environmental Conditions Allows the Near Ambient Pressure (NAP) XPS Analysis of Catalysts

4. XFAS

Manufacturer: easyXAFS

This high-performance XAFS system combines a 1.2 kW XRD-style x-ray tube with advanced optics and detectors to deliver rapid, high-throughput XANES and EXAFS measurements, ideal for catalysis and energy storage research. An optional XRF-style tube upgrade enables efficient X-ray emission spectroscopy (XES) capabilities.

5.XRD

Manufacturer: Bruker

The Bruker d8 Advance X-ray diffractometer is a theta-theta instrument that is configured for analysis of powder samples. This instrument is configured with a Cu x-ray tube, a number of slits and filters, a rotating sample holder, and a position sensitive LynxEyeXE detector.

6. Gas Flow Reactors

Manufacturer: P&ID Engtech / Micromeretics

Isothermal Fixed bed flow reactors are used as laboratory scale reactors for catalytic screening and kinetic studies of different solid catalysts for gas phase reactions. These are generally operated under dynamic conditions, whereby the reactants are continuously fed to the reactor and products are continuously collected for analysis. These are very important tools for developing new catalysts candidates for industrially important processes. All these reactors can be operated under a wide range of temperatures (from RT to 1000 °C) and pressures (up to 100 bar). All these reactors are equipped with Gas chromatographs for continuous on-line gas analysis.

7. Batch reactor

Manufacturer: ILS, Parker, Buchi

We are equipped with high-throughput (HT) systems and single versatile batch reactor vessel capable of handling temperatures up to 350 °C and pressures up to 120 bar. The units enable efficient screening and optimization of reaction conditions under demanding thermal and pressure environments.

8. Glovebox

Manufacturer: Mbraun

Around 30 gloveboxes are used to handle air sensitive compounds and are filled with inert gases. Their atmosphere is of very high purity and allow to load and unload vessels for the preparation, the characterization of the catalytic screening of highly reactive compounds.

9. Chromatography analyses

Manufacturer: Agilent and Thermo

Our chromatography capabilities include HPLC, UPLC, GC-MS, and RGA GC systems, providing robust analytical support for a wide range of compounds. In addition, we have a dedicated petroleum lab platform equipped for SIMDIS and DHA analyses, enabling accurate characterization of complex and heavy feedstocks.

10. Surface Characterization

Manufacturer: Micromeretics, Malvern, Mettler Toledo

Our lab is equipped for advanced material characterization. We use Micromeritics ASAP 2420 and 2020 analyzers for surface area, porosity, and metal dispersion via physisorption and chemisorption. Thermal properties are studied with TGA and DSC up to 1600 °C. Particle size and charge are measured using Malvern ZEN 3600 and Mastersizer 2000. We also have FTIR-pyridine for acidity analysis, a TPD/TPO system for temperature-programmed studies, and other spectroscopy techniques for in-depth catalyst characterization.

Team expertise

- Affiliated faculty

- Platform staff

Research expertise

Catalyst Design and Mechanistic Understanding:

C1 Chemistry and CO₂ Valorization:

Methanol-to-Olefins, Hydrocarbon Upgrading, and Crude-to-Chemicals:

Plastic Waste and Complex Feedstock Valorization:

Photocatalysis and Electrocatalysis for Energy:

High-Throughput Screening and AI-Driven Discovery:

Reactor Engineering and Process Intensification:

In Situ and Operando Characterization:

Ammonia Cracking and Hydrogen Carriers:

Sustainable Catalysis and Industrial Impact:

Platform Leadership Committee

CHAIR, PROFESSOR

JORGE GASCON

Chemical Engineering

PROFESSOR

PEDRO CASTANO

Chemical Engineering

PROFESSOR

LUIGI CAVALLO

Chemical Science

PROFESSOR

KUO-WEI HUANG

Chemical Science

ASSOCIATE PROFESSOR

YOJI KOBAYASHI

Chemical Science

PROFESSOR

MAGNUS RUEPING

Chemical Science

ASSOCIATE PROFESSOR

JAVIER RUIZ-MARTINEZ

Chemical Engineering